In today’s diverse industrial landscape, a shared concern unites businesses of all sizes and sectors: safeguarding the health of their workforce.

Common health hazards transcend industry boundaries, posing risks to employees and the longevity of enterprises. As an employer, mitigating these hazards is not only a moral imperative but also essential for maintaining operational efficiency.

You may find yourself confused when it comes to understanding and overcoming occupational health challenges. However, you need not worry. In this blog, we will explore the pervasive health hazards that affect various industries.

Mitigate Fire-Related Health Hazards

Fire-related incidents are an ever-looming threat across industries, from manufacturing plants to office complexes. These occurrences bring forth a host of severe health risks for your employees, including:

- Smoke inhalation

- Burns and scalds

- Toxic gas exposure

- Trauma and stress

If you are a factory owner, then you are at a higher risk of dealing with these fire-related incidents. Factories are more susceptible to fire-related incidents due to the intricacies of industrial processes and the presence of machinery. According to a report, 2021 saw a staggering 129% year-on-year increase in factory fires. It’s concerning that 2022 likely exceeded this alarming record.

However, while fire suppression is crucial, exercise caution with substances like Aqueous Film-Forming Foam (AFFF) firefighting foam. As per TorHoerman Law, these forms are loaded with PFAS chemicals, which are linked to cancer diagnoses and other adverse health effects. These health outcomes have led those affected to file an AFFF lawsuit to recover the settlement amounts.

According to estimates, the AFFF lawsuit settlement amounts may range from $40,000 to $300,000 or even more. This compensation is dependent on factors such as the nature of the injury, employment loss, personal loss, emotional trauma, and more. However, victims require a competent attorney to navigate the complex legal framework and secure the desired compensation.

Safeguard Against Airborne Pollutants

Today, a growing number of Americans work in environments where airborne pollutants threaten their health. These airborne particles particularly make them vulnerable to various respiratory illnesses.

As per data from the U.S. Bureau of Labor Statistics, there was a 4,000% surge in employer-reported cases of respiratory illnesses during the year 2020. This significant surge underscores the urgent need for industries to take proactive steps to protect their workforce.

Improved Ventilation and Air Filtration Systems

One key strategy to safeguard against airborne pollutants and respiratory risks is the enhancement of workplace ventilation and air filtration systems. You can invest in high-efficiency particulate air (HEPA) filters that can effectively remove harmful particles and pollutants from the air. Ensuring proper maintenance of these systems is essential for their continued effectiveness.

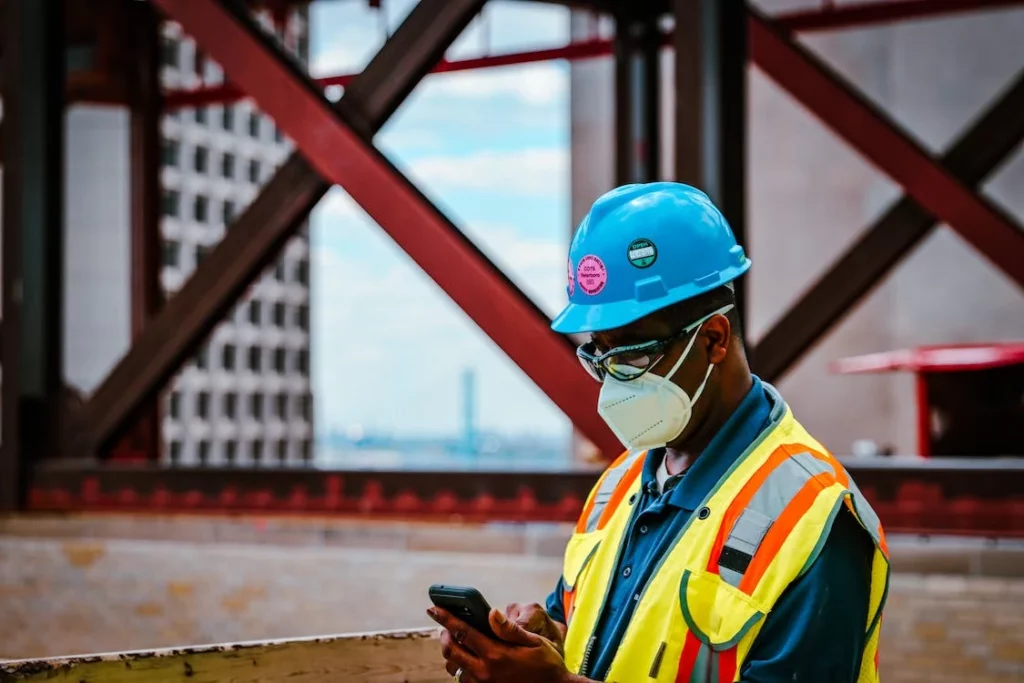

Respiratory Protective Equipment (RPE)

Another critical measure is the provision of appropriate respiratory protective equipment (RPE) to workers exposed to respiratory hazards. Being an employer, the onus is on you to ensure that your employees receive proper training on how to wear RPE correctly. You can also train them in the management of this equipment, enabling long-term use.

Hazardous Material Handling Protocols

Industries must establish and enforce stringent protocols for the safe handling, storage, and disposal of hazardous materials. Proper labeling, containment measures, and emergency response plans should be in place to minimize the release of harmful substances into the air.

Education and training programs on these protocols are crucial for ensuring that your employees are aware of and adhere to best practices. This reduces the risk of respiratory illnesses associated with airborne pollutants.

Promote Worker Safety in Noisy Environments

In the United States, the issue of noise pollution in the workplace is a pressing concern. According to the National Institute for Occupational Safety and Health (NIOSH), nearly 22 million U.S. workers are exposed to hazardous noise levels at work each year. This pervasive problem not only affects your employees’ comfort but also poses serious risks to their health. To address this issue effectively, proactive measures are essential.

To combat noise pollution, you can implement engineering controls, such as soundproofing and acoustic barriers, to minimize noise levels at the source. As an employer, you can provide workers with earplugs or earmuffs to reduce the intensity of high noise levels. Plus, you must ensure that employees are trained on the correct use of these protective measures.

Moreover, regular assessments of noise exposure levels are vital to identify areas where noise pollution is a concern. You can use sound level meters to monitor noise levels and track potential fluctuations. Based on these assessments, adjustments to work schedules or equipment can be made to reduce noise exposure.

Strategies to Address Chemical Exposure Risks

The need to address chemical exposure risks in industries has become increasingly urgent. Since April 2020, there have been over 470 chemical incidents, including chemical fires, explosions, and toxic releases. Extracted from the Coalition to Prevent Chemical Disasters, the data underscores the urgent need to embrace strategies to mitigate these risks.

Rigorous Chemical Inventory Management

Properly documenting and managing the inventory of hazardous chemicals is a fundamental step. This strategy involves maintaining up-to-date records of the types, quantities, and locations of chemicals within the facility. With accurate information readily available, you can respond swiftly in case of leaks, spills, or other emergencies.

Implement Safe Handling Procedures

Establishing strict guidelines for handling chemicals is vital. This includes adherence to recommended storage conditions, safe transport practices, and protocols for mixing or diluting substances. By enforcing these procedures, you can reduce the likelihood of chemical exposure incidents and their potentially devastating consequences.

Final Thoughts

In the ever-evolving landscape of industries, prioritizing the health and well-being of your employees is more than just a moral imperative. Today, it’s a strategic necessity that enables you to ensure employee well-being while boosting their productivity and your business’s bottom line.

These strategies can help employers across industries foster a sense of safety and resilience among employees. By doing so, they can experience a positive business outlook and achieve success.